SA1750CR Premium Chromium Carbide Overlay Plate

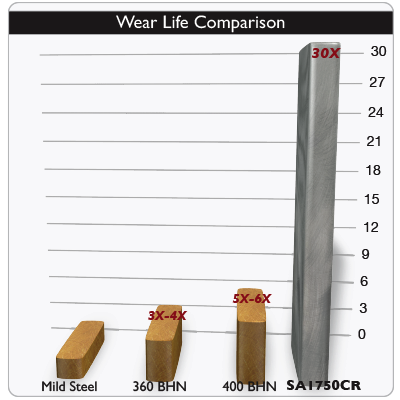

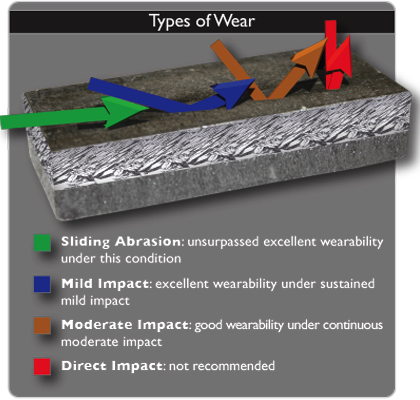

SA1750CR sets the industry standard for controlling abrasive wear. SA1750CR is a Chromium Carbide Overlay Plate consisting of a Hypereutectic Matrix with at least 50-60% Chromium Carbides metallurgically fused to an appropriate steel substrate. This large amount of hard chromium carbides allows SA1750CR to thrive in environments of extremely high abrasion.

The hardness of a SA1750CR overlay is a composite of the hard chromium carbides (1750 Vickers), with that of the tough, austenitic matrix. The macro-hardness of the overlay is 55-62 HRc, depending on the thickness of the overlay.

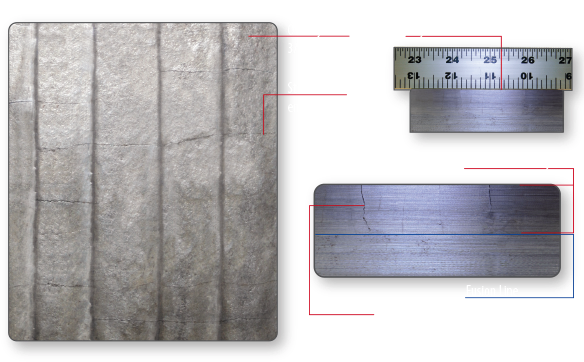

The Chromium Carbide surface is comprised of a series of beads (3/4" to 1-1/2" wide) with many hairline cracks. These cracks are a natural phenomenon created during the overlay process. Cracks in the overlay are both desirable and necessary. They allow the overlay surface to be formed into complex shapes and to withstand impacts that cause other hard materials to fracture.

SA1750CR Iron Ore Chute Liner Case History: Out Performing Brand X

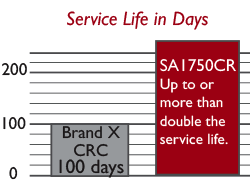

SA1750CR Premium Chromium Carbide Overlay Plate was installed as a liner in an iron ore sizing screen oversize outlet chute. This chute transports 12 to 20mm pieces of iron ore at a rate of 400 tons per hour. SA1750CR was put up against another brand of chromium carbide overlay plate to see which would last longer.

After 100 days the Brand X Plate was showing heavy wear and needed to be replaced. The SA1750CR liner was showing minor wear and did not need replacing.

SA1750CR is also available with the RapidFlow Premium Smooth Surface Finish.